Virtual reality for layout planning

Reduce waste by interleaving simulation, emulation and human factors into one powerful visualisation

Reduce waste by interleaving simulation, emulation and human factors into one powerful visualisation

Fewer reported issues

Reduction in time to

adapt work cells

Faster product

time to market

Reduction in production

line injuries

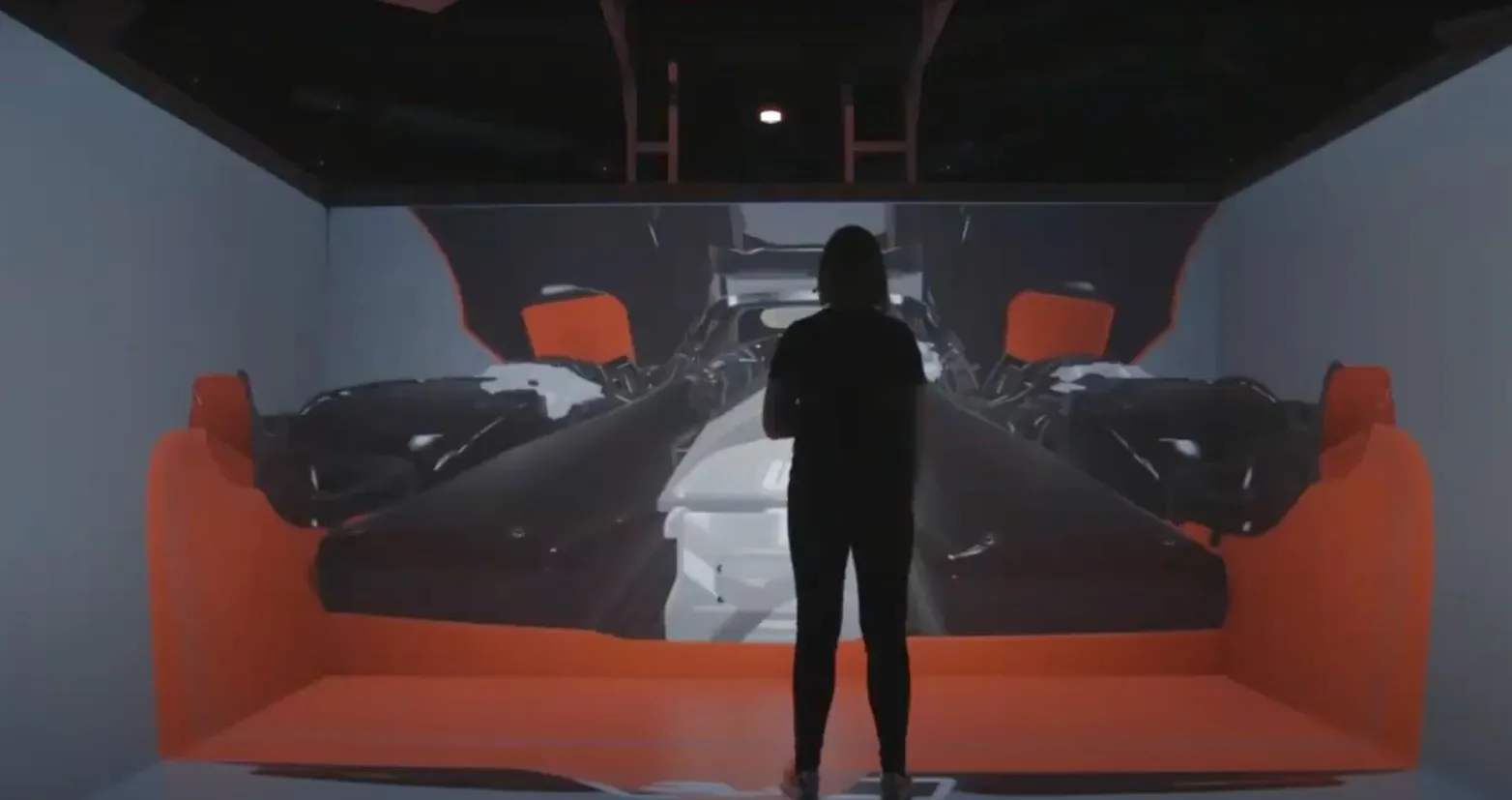

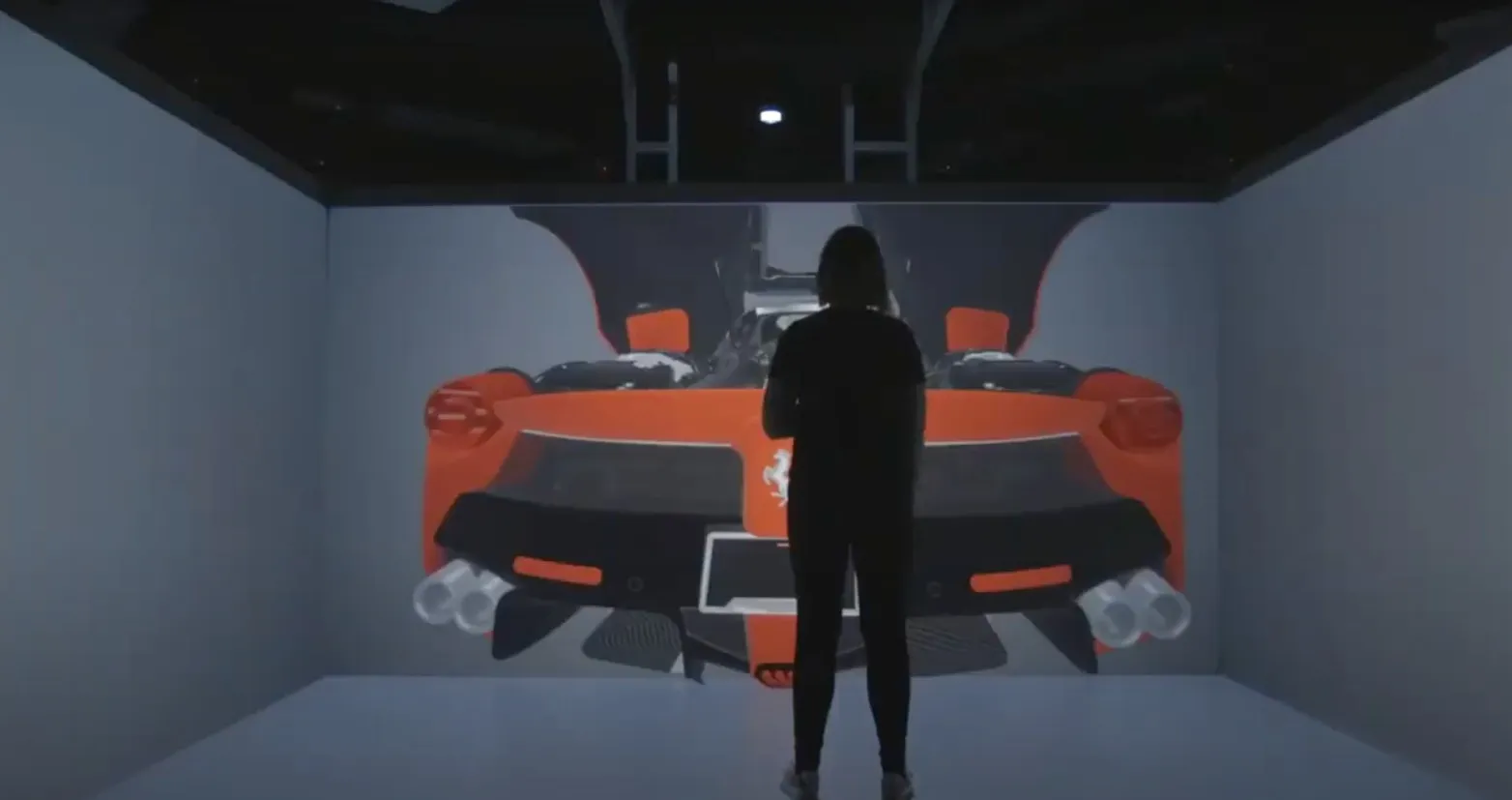

Layout planning requires that simulation, emulation and human factors are interleaved to create the optimum output. Visualisation brings these different dimensions together for effective decision making and communication.

An immersive walk through, or virtual production run ensures that nothing gets missed. Data can be overlayed on a scene for extra context, the impact of different scenarios can be explicitly illustrated.

Share your ideas and concepts with your colleagues and get buy-in for your projects.

Ensure colleagues are comfortable with proposed transformations - this can range from those on the front line to those in the boardroom or even the wider community.

Involve your customers and suppliers early. Share up to date information with all involved parties through a tightly controlled, but easily accessible platform.

Reuse virtual assets to significantly reduce work cell design and adaptation cycle time.

Evaluate impact and feasibility of proposed modifications.

Whether moving a huge subsea structure through a small village with millimetres to spare or joining submarine sections together without rework, visualisation allows you to do the extraordinary.

“The Virtual Factory gives us a big-picture view, so we can identify areas to improve efficiency, cut out waste, and prevent problems in the physical world. This has resulted in more innovation, flexibility and productivity.”

"Our engineers come up with more ideas than they would in 2D because they clearly see the obstacles they face and what needs to be done to overcome them."

Read more about how some of our customers use visualisation to overcome their challenges.

Bring all your digital assets together in one immersive experience

Our products